+49 (0)40 881 56 88 0

2C injection moulding

Combination of two different polymers in one injection moulding process to save later assembly steps.

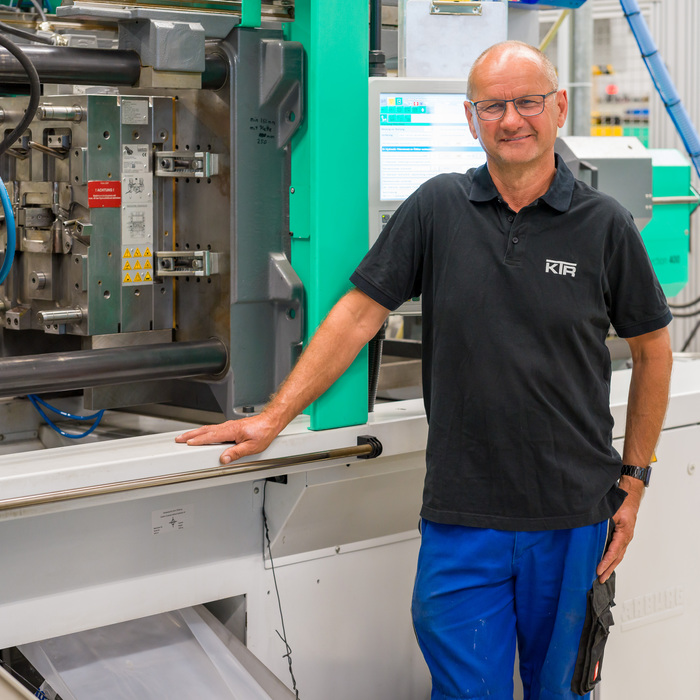

High quality plastic components are indispensable in a wide range of industries. Whether in the automotive industry, electronics sector, medical technology, aerospace, or construction industry as well as many other areas – plastic injection moulded parts are used wherever precision, reliability and durability are required.

As a strong partner for these industries, KTR offers customized solutions for your company and has the highest standards of quality and service. Thanks to our many years of expertise and the latest manufacturing technologies, we always deliver outstanding results in order that our parts can be used in aircrafts, cars and operating theatres, and the list goes on.

At KTR, you always get the right solution for your specifications.

Customer-specific colourings and formula adaptations are also possible at any time because special materials are standard for us! We will be happy to advise you on how to achieve the optimum properties for your product.

Purchasing an injection mould can be a high initial investment. That is why our mould management team coordinates with you from the design phase to provide you with support in designing your parts. After planning and procurement, we take care of your moulds throughout their entire life cycle. You can benefit from the know-how of our specialists.

There is a reason that we have been successful in plastic injection moulding for more than 50 years. We are only satisfied when our customers are satisfied with us, our products and our service. This high standard is reflected in each of our services.

Rely on a partner who can provide you with exactly the right plastic injection moulding products and services you need for your project – we look forward to getting to know you!

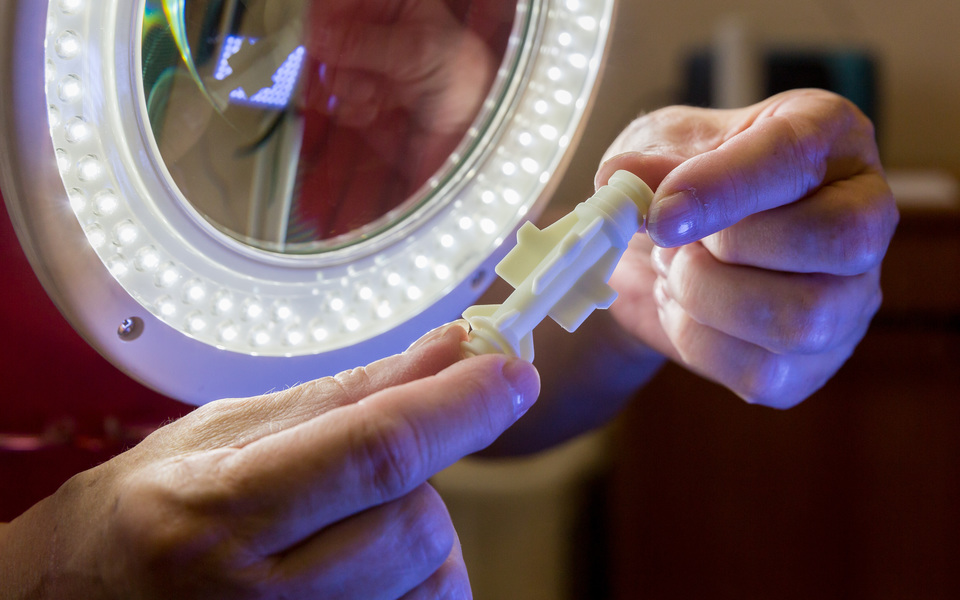

Industry: Medical technology (dental)

Application: By the dentist in the patient's mouth

Mould type: 16-fold with hot runner

Material: PP

Features: Tight tolerances so that upper and lower part can be clipped together in automatic assembly

Industry: Medical technology (dental)

Application: Roller for mixing impression materials

Mould type: 8-fold with hot runner

Material: PC

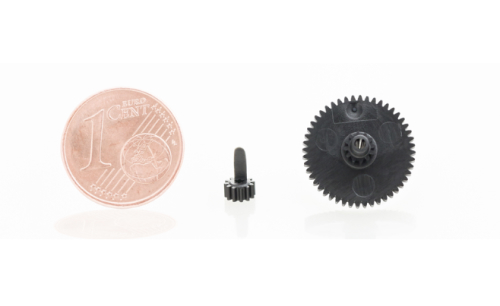

Industry: Mechanical engineering

Application: Gear in a sensor

Mould type: Family mould

Material: POM with colour batch

Features: Smallest part weight with 0.02 g and accuracy of 0.01 mm

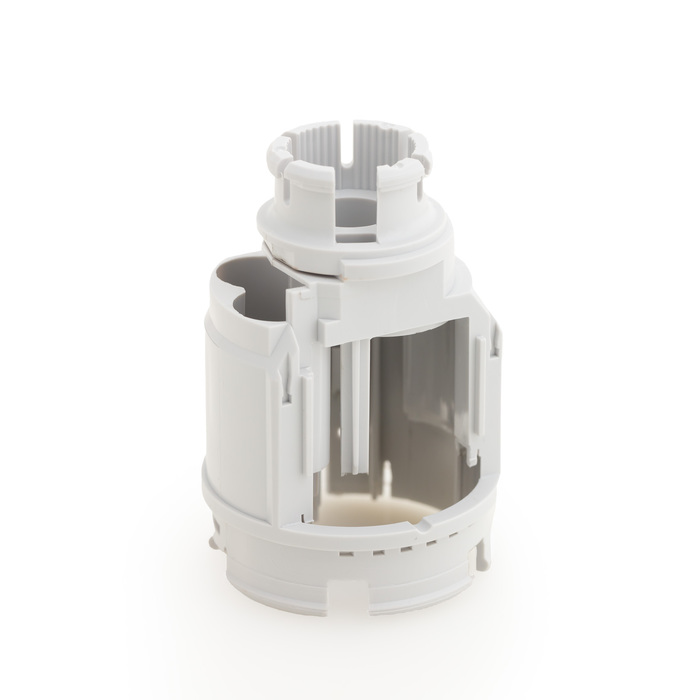

Industry: Digital thermal management

Application: Intelligent thermostat

Mould type: 1-fold

Material: PC/ABS blend

Industry: Shipbuilding

Application: Light cover on ship

Mould tpye: 2-fold with hot runner

Material: PC crystal clear

Special features:

Industry: Measurement technology

Application: Housing for device

Mould type: 3 tools for assembly

Material: PC/ABS blend with colour batch

Special features:

Branch: Aviation

Application: Door in aircraft

Mould type: 1+1 mould

Material: PEEK

Special features:

Industry: Aviation

Application: Cable holder in aircraft

Mould type: 1-fold

Material: PEI

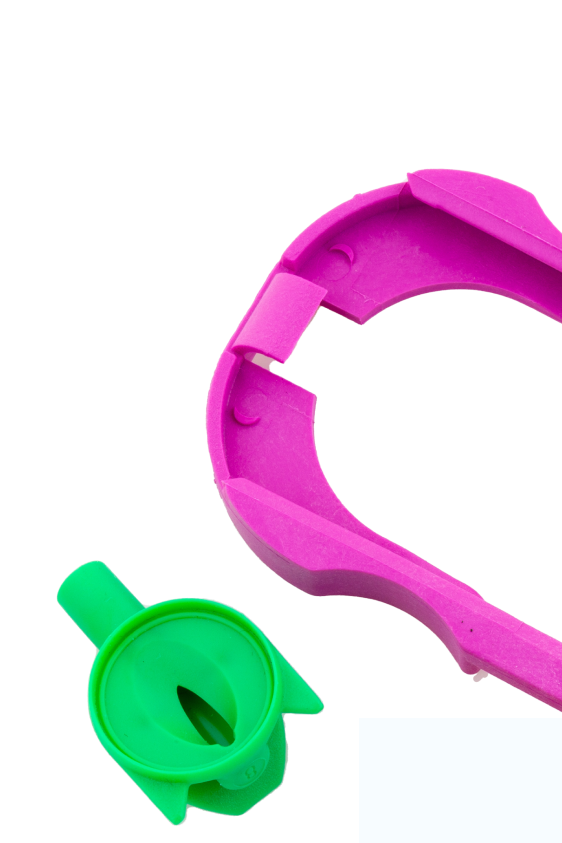

Industry: Promotional items

Application: Ice scraper for car

Mould type: 2C mould

Material: ABS + TPU

Special features:

Industry: Medical Technology

Mould type: 2C mould

Application: Through the soft component a button can be operated

Material: PP + TPE

Contact us with your individual requirements – together we will work out a perfect solution!

Whatever your requirements, the experts at KTR will find the right solution. In doing so, we always focus on your personal wishes and inform you transparently about the possibilities and limits of plastic injection moulding. Use our expertise for your project and request your consultation now!

Contact