+49 (0)40 881 56 88 0

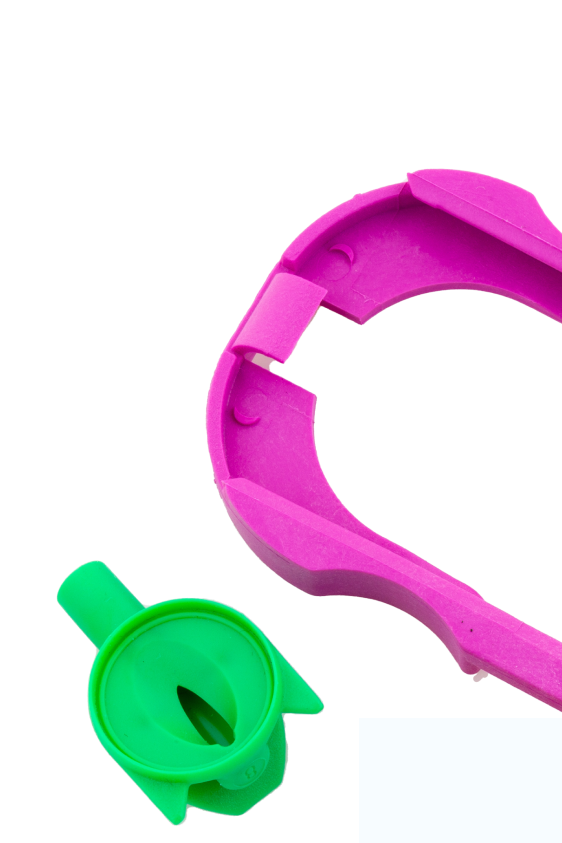

2C injection moulding

Precise production of multi-component parts for a variety of material combinations.

As plastic technology experts, we understand the requirements and needs of our customers: high quality plastic components, durable and long-lasting parts for petrol station technology, aeronautical components with continuous batch traceability, medical parts with the highest cleanliness and more – and for fair prices and reliable services. As a plastic injection moulding company with strong service, we will find a solution for your needs.

Our goal is long-term cooperation with our customers. Therefore, we do not only offer excellent products and results in high performance plastics, but also proactive service that goes above and beyond. Our processes are as efficient as possible to achieve quick production and delivery times. We can often advise customers how to save on costs and time in the design phase, thanks to our expert knowledge. You can depend on our expertise and years of experience.

Customer satisfaction is the highest priority. That is why we have individual consultation, support and manufacturing “made in Germany”: since our founding, we have been committed to Germany as a production location – this is the only way we can guarantee the consistently high quality of our products.

Your project can benefit from our expertise and commitment from our employees. Contact us to discuss your project with experts – you are in good hands!

We have many types of plastic available – speak to one of our experts about your individual requirements.

Contact