+49 (0)40 881 56 88 0

Planning

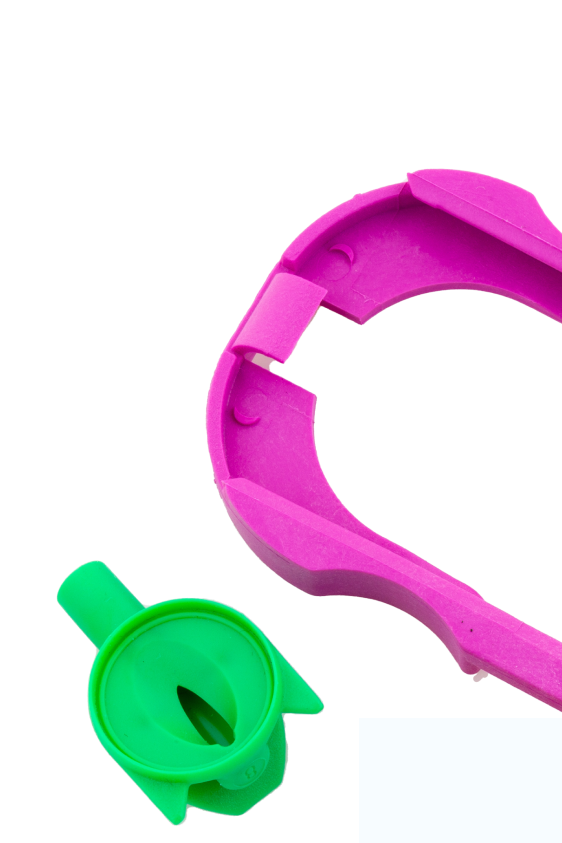

Through careful analyses, we plan the best possible injection mould in close consultation with you.

Designing the mould for injection moulding is an important decision when producing plastic components: in series production, precision and durability are important to meet the requirements of mass productions. In the possible prototype phase, more simple injection moulding tools are used to validate the design and carry out functionality tests.

KTR are experts ready to find the right tools for your individual project requirements. In the design phase, we can then guarantee that the optimal dimensioning of your plastic components will mean saving on costs and time.

We can help you develop the right moulds for your project – our experts will be happy to provide you with individual advice at any time!

FAQ

What are injection moulds?

Injection moulds are specially designed moulds in plastics technology. They are used to form molten polymers into a specific shape. After the material has cooled and hardened, the raw plastic part is finished.

What materials are injection moulds made of?

As a standard, injection moulds are made of hardened tool steel. Thanks to the wide range of steel grades, we can determine the right material for every requirement. Steel tools are particularly durable and resistant to wear. In exceptional cases, aluminium is also a suitable material, as it is cheaper and lighter – this may be the case, for example, when manufacturing prototype moulds.

How long does it take to produce an injection mould?

The production of an injection mould can take between a few weeks and several months, depending on the complexity of the mould, material used and size of the project. The manufacturing time can also be influenced by factors such as the quality of the mould design and experience of the manufacturer.

What are the main factors that influence the quality of an injection mould?

The quality of an injection mould depends on several factors, including:

Does KTR produce injection moulds?

Since 2020, we no longer have our own mould making department. This means we are flexible in our choice of suppliers and can find the most suitable toolmaker for your requirements. Whether high-precision series tools or prototype tools when time is of the essence: we have the right partner and procure the right tool for you.

Contact