+49 (0)40 881 56 88 0

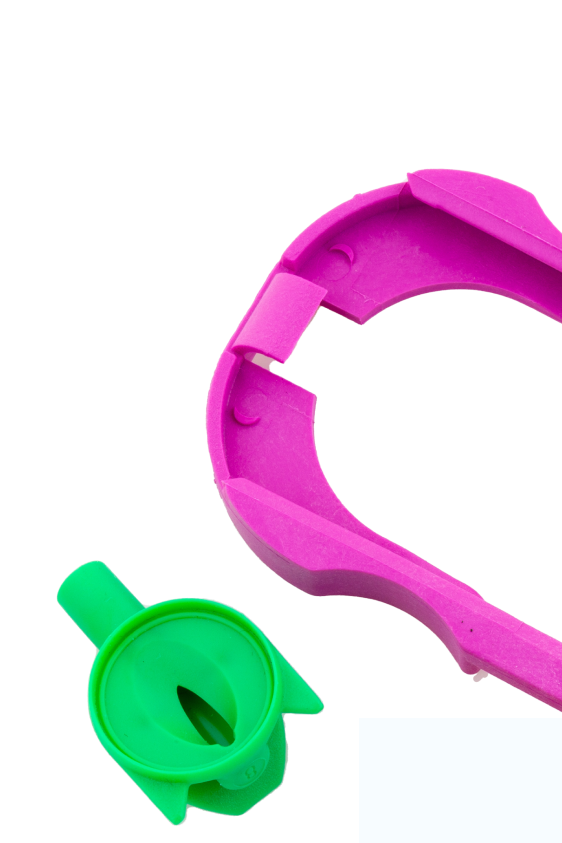

Ultrasonic welding

Joining of plastic parts without the addition of solvents or adhesives

As a long-existing company in the plastics industry with close contact to our customers, we not only offer injection moulded products, but are also happy to take over the subsequent process steps. For example, we manufacture the upper and lower parts for an aircraft handle by injection moulding, and then join the two parts together with screws and nuts in our assembly department. Afterwards, the handle is painted and then subjected to a 100% inspection by our quality assurance department. As another example, we injection mould two half-shells for a floating measurement device. We insert a magnet into these before they are ultrasonically welded watertight. Here, too, a 100% leak test is carried out.

Do you have specific requirements for your finishing? Talk to our experts - together we will find the solution!

Kunststofftechnik Hans Rethwisch GmbH has been manufacturing technical injection moulded precision parts since 1969. In doing so, the satisfaction of our customers is close to our hearts - to this end, we develop customised solutions with expertise and experience and attach great importance to the high quality of our work.

Request your non-binding offer for your specific project - we will advise you individually and comprehensively!

Contact