+49 (0)40 881 56 88 0

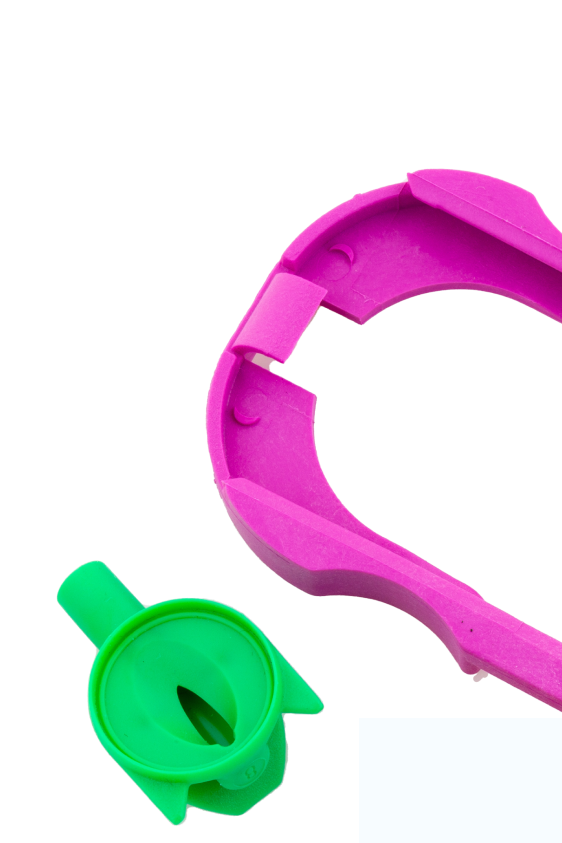

The advantages of multi-component injection moulding for innovative plastic solutions

Instead of gluing or welding two plastic components made of different materials, they are injected directly onto each other in 2C injection moulding. This not only saves assembly costs, but also time. The combination of different materials in a single step also enables the realisation of parts with different colours, hardness or even functionalities. The hard component can be e.g. ABS, PC, PBT or PA, while the soft component can be e.g. TPU or another TPE. Typical applications are soft handles or seals that are integrated into hard plastic parts. Without any additional assembly steps required, this process thus offers a high degree of design freedom, efficiency and cost savings.

KTR can develop customised solutions that are precisely tailored to your individual requirements and ensure an optimum fit, thanks to years of expertise in multi-component injection moulding.

Advantages of 2C injection moulding:

- Wide range of combination options

- Improved functions & product properties

- Time saving due to elimination of assembly or joining

- Sustainable cost optimisation

- High design flexibility

Contact

Our sales team will be happy to advise you, just give us a call or make an appointment